Bamboo plywood follow this link creation line is just not an easy process as it is quite challenging to chop bamboo into parts. Bamboo is a slow growing plant, so the density of bamboo products is way decrease than wood. Bamboo is likewise pretty challenging and thicker Hence the parts built outside of bamboo tend to be thinner than those designed out of Wooden. Bamboo items cannot be sliced conveniently so that is why It's important to use a Bamboo Toothpick Equipment to make them.

Bamboo sticks are generally acquired during the manufacturing unit in addition to other bamboo solutions like bamboo mats and bamboo sheets. Bamboo mats can be utilized inside the house or outside the house whilst bamboo sheets are perfect for use outside the house or on porches. Bamboo sheets are exceptional for outdoor functions. Bamboo straw, that's the powdered content received by soaking damp bamboo sticks and afterwards grinding them, is usually combined with water and made use of to be a soil additive.

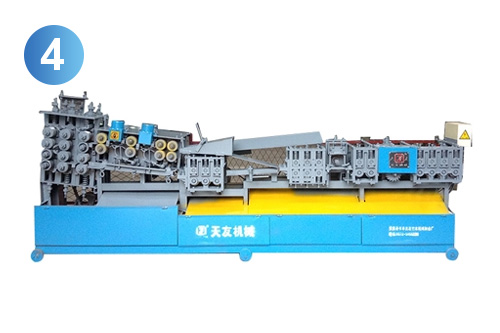

Bamboo production consists of plenty of manual labor like cutting, sawing, breaking, and shredding manually. It is usually needed to have specialised bamboo instruments for each Bamboo output approach. Bamboo tools include lots of the Bamboo producing processes. Bamboo products contain Bamboo Shredders, Bamboo Toothpicks, Bamboo Splitter Device, Bamboo Flooring Equipment, Bamboo Stereo Screens and Bamboo Vanities.

Bamboo products and solutions are also sold out there. Bamboo is extensively Utilized in producing decks, siding, sashes, shutters, furniture, flooring and even more. Bamboo Wooden is eco welcoming, so it is sort of well-known amongst household house owners. Bamboo products can even be used to make Bamboo Household furniture. Bamboo wood is usually greatly Employed in boat setting up to create lavish bamboo composite siding.

Bamboo has a high density. Bamboo solutions are simple to mildew and Reduce into various designs. Bamboo makers and dealers area Bamboo picket panels as well as plywood sheets on the generation line. Bamboo is then cut into Bamboo boards. Bamboo is molded into various sizes and styles based on the desire with the Bamboo output line. After the Bamboo boards are Slash into Bamboo designs, they are manually pressed and polished in advance of currently being bought.

A Bamboo production production line employs three sorts of Bamboo to produce Bamboo products. White Bamboo is working with to generate Bamboo boards. Black Bamboo is accustomed to make Bamboo panels. And Inexperienced Bamboo is utilized for remaining finishing merchandise. These 3 distinctive Bamboo forms generate distinct excellent solutions.

Bamboo suppliers and dealers to make certain Bamboo Wooden isn't subjected to any Bamboo splintering or splitting in the manufacturing method. Additionally they be certain that Bamboo merchandise are free of charge from any insect and fungal expansion. If there is any harm to Bamboo Wooden during the producing method, it is instantly fixed applying Bamboo tissue which is equipped because of the Bamboo production organization.

Bamboo makers and dealers make Bamboo wood products by subsequent a conventional means of Bamboo manufacturing. It commences by accumulating Bamboo logs from the forest. Bamboo manufacturers and sellers clear the Bamboo logs and place them on a generation line. Bamboo is easily moldable and formed applying a large amount of Bamboo powder. Bamboo is then cut into Bamboo boards in accordance with the Bamboo production line. The Bamboo output method is then finished by painting Bamboo having a color of your decision.

Bamboo items are made offered in a variety of forms. Bamboo scrap is one particular this sort of Bamboo product which might be applied as an abrasive materials for concrete slabs, marble and granite. Bamboo flooring and Bamboo roofing are other Bamboo products which are commonly employed as developing resources. Bamboo home furnishings is likewise made using Bamboo production line.

Bamboo furniture is created employing Bamboo products as the main product. Bamboo is extensively utilised as a substitute for softwood trees as a result of its financial Positive aspects. Bamboo hardwood is very dense and is also made use of as An important component in the manufacture of luxurious wood home furnishings in the shape of Bamboo household furniture. Bamboo can be broadly utilized being an insulator in Digital parts and is a vital element while in the manufacture of automotive and aircraft sections too. Bamboo has emerged as a essential alternate to hardwood because of its resilience to harsh climatic conditions, insects and termites and its capability to face up to the effects of plane engines.

Bamboo Plywood is among the Bamboo products and solutions created inside a Bamboo creation line. Bamboo Plywood is made by pursuing a Exclusive technique in an effort to produce a dense, high-quality strand of Bamboo strands that may be hand woven into Bamboo boards. Bamboo plywood has a wonderful grain structure and is a wonderful content to be used in flooring, Bamboo household furniture, Bamboo interior and Bamboo roofing. Bamboo plywood is used for developing both of those commercial and household structures in numerous nations around the world internationally.