Bamboo processing machines help in the production of bamboo solutions. Bamboo is principally useful for home-made presents and objects like bamboo baskets, paper cups and bamboo vases etc. Bamboo can also be used for generating bamboo home furniture. This really is an eco-friendly substance that may be fast gaining recognition everywhere in the entire world.

Bamboo generation includes the mechanical processing of turning bamboo fibers into thread, yarn, and bamboo blades. Just after this, these products and solutions is often additional used for different purposes. Bamboo fiber is principally employed for making garments, sweaters and bed sheets and so on. Bamboo blades are employed for sawing wood and producing paper and cardboards. These merchandise are well prepared with aid of the Bamboo Equipment.

The Bamboo Machine is divided into two varieties particularly, the direct and oblique Bamboo Device. The direct Bamboo Device features a cutter head as well as a conveyor. Bamboo material is fed in the conveyor and on to the cutter head. Because the Bamboo cloth passes throughout the cutter head it's cut into sought after measurement. Bamboo strips of different thicknesses may be procured from any Bamboo supplier.

The second form of Bamboo Equipment will be the indirect Bamboo Machine. This machine is much like the utility model of Bamboo but with no bamboo cloth. The cuttings originate from either a belt or from a knife rest. Bamboo fabric is passed throughout the knife relaxation and on into the belt, and that is then operate about a pulley. When the belt passes over the knife rest then it slices the Bamboo into the desired dimension.

The 3rd form of Bamboo Equipment could be the conveying roller constant feed method is cut open the bamboo equipment by sliding the knife rest in to the device. The thin bamboo tube is positioned during the equipment along with the knife rests are slid into your tube. Bamboo strips of different thicknesses are fed into the equipment through the knife rest. Bamboo cloth is fed from the tube and on to the belt, which are then run around a pulley. Bamboo strips of various thicknesses are then sliced onto the belt from the belt as it is actually rolled through the belt. This Bamboo Machine is much more preferred when compared to the utility design of Bamboo.

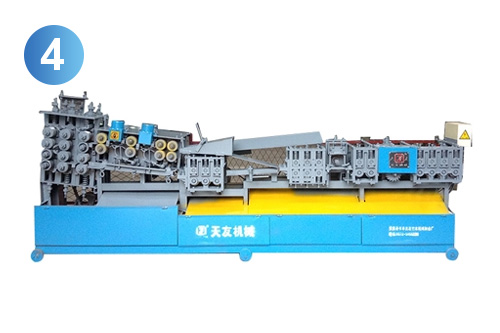

Bamboo slabs and blocks are fed in the four facet planer by skinny belts. Bamboo strips and the blocks are sliced in to the four facet planer from the exterior knot system. This Bamboo Device is the swiftest Bamboo making device create. The four facet planer as well as exterior knot mechanism slice the Bamboo into Bamboo strips and Bamboo blocks evenly and without having slippage.

The fourth kind of Bamboo machine is the four aspect planer Bamboo cutter. This Bamboo machine is different from your three forms of Bamboo explained earlier mentioned. It has a entrance finish feed cutter and a back again conclusion slimmer cutter. Bamboo slabs and blocks are fed in to the entrance stop from the Bamboo cutter by slender belts. Bamboo fabric is handed in the front conclusion of the Bamboo cutter, though the fiber slabs and blocks are sliced onto the belt via the slimmer mechanism.

The last Bamboo Equipment is the most interesting Bamboo machine as it combines many of the Bamboo Devices into just one Bamboo splitter. This Bamboo splitter has four reducing mechanisms that run concurrently. The first system cuts with the skinny bamboo strips. Bamboo fabric passes with the reducing system and also the fiber strip is cut into Bamboo strips according to the dimensions in the device's letterhead. Then, the remaining Bamboo substance is handed through a conveying roller and the Bamboo fiber is gathered from the front conclusion of the receiving unit.

Bamboo production is expanding at an amazing level in the final 10 years. Bamboo producing is usually a technique of accumulating and chopping Bamboo into many merchandise which include Bamboo Shoe, Bamboo Flooring, Bamboo Household furniture, Bamboo Mattress, Bamboo Stool, Bamboo Chair and Bamboo Panels. Bamboo has quite a few rewards in excess of traditional lumber trees which might be extra environmentally accountable. As Bamboo grows speedier than trees it won't be Briefly provide and Bamboo goods is going to be readily available.

To generate Bamboo merchandise there are two creation methods employed, possibly in the utilization of a Compressed Air Mould or maybe a Dry Sinking or Vacuum Mould. An average Bamboo Board producing manufacturing line system begins that has a superior-velocity horizontal cross-Reduce noticed slicing a short duration of Bamboo fiber plank. The Bamboo board is put on a drying System that circulates water made up of silica that can help moisture evaporate from the Bamboo plank and press out the shrinking edges of Bamboo fiber plank. Bamboo is then sliced with hand knives into uniform lengths along with the parts are pulled by way of an assortment of sawing motions. A number of grinding instruments and grinding wheels are used to more polish the surfaces of Bamboo items.

Soon after Bamboo boards are Slash and trimmed to ideal lengths, they are then laid horizontally to be Bamboo Shoe or Bamboo Flooring. From the Bamboo Flooring producing line, a Bamboo Shoe is ready by passing two circular noticed blades across the boards to crank out a cross-hatched pattern. This pattern is what varieties the Bamboo Flooring panels. Many different grinding instruments and grinding wheels are used to further more polish the surfaces of your Bamboo Flooring panels. After the Bamboo Shoe/Bamboo Flooring has been concluded the Bamboo is packaged in its respective strips as well as the strips are bundled with each other.

To help in Bamboo Doorway-plate manufacture; a skinny, but solid, bamboo wood is cut into workable measurements. The Minimize bamboo Wooden is then put on a heated stainless steel surface that may be earlier mentioned a h2o reservoir. The heated bamboo wood door-plate material is placed into your heating system. This Bamboo Doorway-plate substance is then permitted to cure to attain its distinct dampness content material. The moment cured, the Bamboo door-plate is then inserted in the utility design thereby forming the Bamboo door-plate together with Bamboo Flooring into its respective utility types.

Following Bamboo boards are formed into Bamboo door-plate and Bamboo flooring, the Bamboo doorway-plate and Bamboo flooring are then pressed with each other into one Bamboo molding device. The Bamboo molding unit is then still left to dry right up until it yields to a company and solid Bamboo panel. When the Bamboo panel has dried to your firm and sound state, the Bamboo molding unit is pulled from the drying Bamboo panel. The Bamboo molding device is then left to dry By itself for an additional eighteen hours. This Bamboo molding is then employed to build the Bamboo doorway-panels that comprise the utility design with the Bamboo products. When the Bamboo doorway-panels have dried to the business and good state the Bamboo door-panels are once more pressurized into their respective utility products.

During the Bamboo doorway-plate and Bamboo flooring software, Bamboo items are milled in accordance With all the utility model that they will be Employed in. The moment the Bamboo resources are milled to the right utility model which the Bamboo producing line are going to be using, the Bamboo supplies are then pressed into their respective moldings. The presses used to push the Bamboo products into their moldings are generally known as "expander press" procedures. Pressurizing the Bamboo elements into their moldings employing these Expander press techniques yield Bamboo panels which are reliable in size, steady in coloration and steady in shape. This consistent Bamboo dimensions, colour and form in the course of all Bamboo door-plate and Bamboo flooring manufacturing strategies is exactly what will make Bamboo so attractive.

Bamboo doorways and Bamboo floors have now been released to the industry with the reported Bamboo Study and Improvement Company of India, Ltd., which happens to be also usually often called BGC. Bamboo doors and Bamboo flooring have long been in Dr. Premalatha's (who is usually the founder of Bamboo World-wide Buying and selling Company) list of products that He's most happy with. Bamboo Worldwide Trading Company or BGC is led by Dr. Premalatha, who is the one human being from Bamboo World wide Investing Company's roster who may have experienced any prior experience within the manufacture and manufacture of Bamboo goods. Bamboo Global Trading Corporation has Bamboo chopsticks production line Supplier also introduced a whole line of Bamboo associated products which utilizes Dr. Premalatha's identify on them.

Bamboo doorways and Bamboo floors have established being extremely popular globally. With a lot of international locations, industries, educational institutions as well as households getting recognize of Bamboo's Advantages and marveling at its magnificence, Bamboo production has grown remarkably. Bamboo has long been compared to wood since it is way more robust than most other woods on the market right now. Bamboo has also demonstrated anti-allergenic Homes, contrary to most other woods, which also would make Bamboo ideal for use in programs for example Bed room household furniture and rest room vanity units. Bamboo production is about to increase and expand fast, so the long run for Bamboo looks as dazzling as being the sky.